How can I get a proper plastic pallet for my industrial applications? This may be the main question you must ask yourself before purchasing the plastic pallets. One of the main factors you must keep in mind is choosing the right classification of plastic pallets based on the loading capacity. I explained the loading capacity of plastic pallets in detail in my previous article; you can find it by clicking here. When it is determined what weight of the cargo the plastic pallet to bear, you have to consider the type of products you have. Any application has its characteristics; you must know what you need the plastic pallets to do. In other words, different types of plastic pallets suit various applications and industries.

Plastic pallets types

Here are some common types of plastic pallets based on their applications:

Nestable Plastic Pallet

These pallets are designed to stack inside one another when not in use. it means the legs of these plastic pallets go into each other, saving space and reducing transportation costs. They are commonly used in food and beverage, pharmaceuticals, distribution, and retail industries.

If you are an exporter, the nestable plastic pallet, is the best choice for packaging your products to keep them safe, convenient, and secure in long-distance transportation. The nestable plastic pallets are compatible with hand-jack and forklifts. They are contributing to easy offloading of your products at the final destination. This makes your clients happy and satisfied. Moreover, the clients can reuse the nestable plastic pallets in a closed-loop system of their own in case it is not mandatory to return them. Using nestable plastic pallets has more benefits than wooden pallets. Nestable plastic pallets are cleaner, more durable, and more economical. In addition, nestable plastic pallets do not need any particular standard such as ISPM-15 or packaging regulations (recycling) in the export process to enter other countries. Furthermore, the tare weights are usually lighter and more consistent than wood pallets, which benefits transportation costs.

In the food and beverage industries, hygiene concerns matter. Therefore, besides the abovementioned factors, the clean supply must also be considered. Using nestable plastic pallets frees you from spoiling or bacteria and fungi growth, breaking down, and causing damage to your product. The integrated structure of plastic pallets is not a good host for foodborne pathogens. It does not allow bacteria penetration into the pallet.

Using different plastic pallet types is common in the supply chains, but Nestable pallets are primarily used when returning the pallets in the policy. As a customer or retailer, if you must return the plastic pallet to your supplier or distributors, the nestable plastic pallet is the best choice. If you have to stock the pallets in the open area, these look more promising and improve visually with evenly stacked nestable plastic. Ultimately, you will save more money by returning a significant number of pallets at once. Because nestable plastic pallets occupy almost a quarter of the space, other plastic pallet designs occupy!

Rackable Plastic Pallet

The racking load capacity means the maximum possible weight a plastic pallet can hold on the racking systems, pallet shuttle systems, forklifts, pallet trucks, and hand-jacks where the center or edges of the plastic pallet are loose, i.e., unsupported condition. The term “rackable” refers to the pallet’s ability to keep its feature on racks, typically in a high-density storage system. Therefore, the rackable plastic pallet is a a type of plastic pallet that is ideal for maximizing your storage space, safe storage, organization, accessibility, and optimization of storage efficiency.

These plastic pallets are designed to fit perfectly on the rack. They can be used in racking systems, where they can support heavy loads without sagging or bending, such as in storage facilities, warehouses, processing and manufacturing environments, static storage, and stack loading and distribution centers equipped with racking systems and pallet shuttle systems.

Rackable plastic pallets are engineered to be strong, durable, long-lasting, impact-resistant, and hit-resistant. Rackable plastic pallets support heavy loads and resist deflection or deformation when placed in a racking system. These pallets are significantly effective on baseless racking systems and even on the floor for tolerating heavy-load products. Hence, rackable plastic pallets are valuable in many heavy-duty and retrieval operations.

Besides improving your floor space vertically, rackable plastic pallets are ideal for clearing up floor space in a warehouse if needed. This will also help you answer some hygiene concerns for the warehouse.

All types of plastic pallets, including rackable plastic pallets, are reusable and have considerable advantages. I can mention durability, resistance to moisture and chemicals, and ease of cleaning and sanitizing. These criteria make this pallet the best alternative to traditional wooden pallets. Wooden pallets have the potential to rot and absorb moisture, infestation, odor, bacteria, and molds and need constant repair and replacement.

Export Plastic Pallet

Export plastic pallets are specially designed for transporting goods and products in short or long distances. The export plastic pallets, like other types of plastic pallets, are engineered based on specific standards to not only withstand the rigors of the journey, handle the heavy loads, and ensure the safety of the goods but also meet export regulations across international borders. That is why they are called one-way plastic pallets, too. Using wooden export pallets risks your products not reaching their destination. The destination customs entry may refuse wooden pallets or require fumigation, which is costly and time-consuming.

When the possibility of returning pallets to their origin is rare, manufacturers usually prefer to produce export plastic pallets from recycled HDPE or PP material to make them cost-effective for exporters. It should be noted that this does not hinder the plastic pallet’s stability, sturdiness, and durability to endure rough handling during transportation. However, suppose you use Export plastic pallets in a closed-loop supply chain system. In that case, you may desire to use export plastic pallets made of VIRGIN material, which provides you with an extremely long life span compared with recycled counterparts.

You may ask whether plastic pool pallets are the same as export plastic pallets in a closed-loop supply chain system. It should be noted that there are 3 main differences between these two. Thanks to our partner in China, Anwood Logistics System Cooperation (ALSCO), which is one the biggest pooling service providers, I cite some points below:

1) Ownership: usually, in the pooling system, the plastic pallets are owned by the pallet pooling service provider, while exporters own Export plastic pallets

2) Construction and feature: plastic pool pallets are often designed to be reusable, durable, and standardized in many times usage and circulations. While Export plastic pallets are designed to ensure the safety of the goods during a journey and comply with international export regulations.

3) Cost of the plastic pallets: plastic pool pallets are rented or leased to customers as needed. The cost of the plastic pallet is typically included in the fee charged for the pooling service. It covers pallet collection, repair, and distribution, while, export pallets are often considered an expense as they are only used for a single shipment and are not expected to be returned to the owner.

Using Export plastic pallets is very common in air freight sections among other types of plastic pallets where the concern is that pallet as a packaging tool must be made at a lower self-weight. They are widely used in health and beauty products, pharmaceuticals, food and beverage, food processing, dairy, etc.

Display Plastic Pallet

Display plastic pallets are widely used for product presentation purposes, such as in retail environments, groceries, supermarkets, malls, exhibitions, and trade shows, e.g., in-aisle or end-of-aisle displays or other settings where goods are showcased, and visuality and accessibility are essential. The display plastic pallets should be designed in a way that has the best functionality. Another feature that should be considered is the lightweight to serve perfectly. The display plastic pallets should be compatible with forklifts and hand jacks for fast and easy movement by workers.

Display plastic pallets can have additional features; for instance, they can be equipped with safety rims, brackets, or clips to securely hold products on the pallets. These customizations prevent sliding the products or toppling over during transportation. Some display plastic pallets may also have a cardholder place, enabling retailers to attach pricing information, promotional materials, etc. It should be kept in mind that other types of plastic pallets can have such customization, too.

In many cases, export and display plastic pallets are considered one type of plastic pallet. However, it is important to bear in mind that not all display plastic pallets can serve as export plastic pallets. The export pallets are focused on durability, standardization, and compliance with international shipping regulations. As I explained in the export plastic pallets section, while display plastic pallets prioritize aesthetics, product visibility, accessibility at the sales point, and enhancing the marketing efforts within a retail environment. Despite the export of plastic pallets, they are intended for in-store display rather than long-distance shipping.

Hygienic Plastic Pallet

All types of plastic pallets are hygienic to some extent compared to wooden pallets since different types of plastic pallets are easier to clean and maintain; however, is it enough when it comes to sensitive industries requiring strict hygiene standards, such as the pharmaceutical and food industries?

A noticeable characteristic of hygienic plastic pallets is their design and materials, among other types of plastic pallets. Closed solid decks and sealed joints do not allow bacteria and fungi to grow. Non-porous surfaces make dirt, moisture, and contaminants difficult to adhere to and accumulate in hygienic plastic pallets. They are easy to clean, wash, and steamed. The hygienic plastic pallets are made of raw material, HDPE or PP food contact injection grade, which is used to comply with food-contact regulations and requirements for use in food-related applications.

Hygienic plastic pallets are designed for use in industries where sanitation and cleanliness are essential. These plastic pallets are easy to wash, clean, and easily dry, contributing to reducing the risk of contamination and the spread of pathogens, mold, and bacteria. They must have solid, non-porous, smooth surfaces to prevent bacteria buildup. Hygienic Plastic pallets are commonly used in applications where hygiene concerns, such as:

- Food & Beverage industry: Hygienic plastic pallets are widely used in food & Beverage processing, storage, and transportation. They help the products to be stable and safe from the production stage until distribution to the consumers.

- Pharmaceutical industry: Hygienic plastic pallets are important for the pharmaceutical industry since the products must maintain integrity and sterile standards. So, a contaminant-free environment is crucial.

- Healthcare: Hospitals and healthcare facilities are downstream of the pharmaceutical industry. They may use hygienic plastic pallets to store and transport medical supplies and equipment safely.

- Laboratories: Hygienic plastic pallets are ideal for laboratories and clean rooms where maintaining a pristine condition is essential.

- Agricultural and Horticultural: Hygienic plastic pallets help store and transport the products in a hygienic environment and prevent contamination.

- Cosmetics sector: Hygienic plastic pallets are also used in product processing, manufacturing, storing, and transporting cosmetics, free of contamination and clean.

- Chemical industry: Chemical manufacturers use hygienic plastic pallets to avoid contamination and ensure the coherence of the chemical products.

- Retail and Distribution: Hygienic plastic pallets can be applied in retail and distribution centers to keep sensitive products that require sanitary conditions safe and maintain quality during storage and transit.

Hygienic plastic pallets can be used in any industry where hygiene attention matters. Any setting that demands sanitation standards and safe, clean, and free-contaminant goods during storage and transporting can enjoy using hygienic plastic pallets.

Reversible Plastic Pallet

A type of plastic pallet is named reversible when a plastic pallet can be used on either side facing up. This feature gives users a flexible and versatile plastic pallet to handle different products. Reversible plastic pallets are strong enough to carry heavy loads and have good resistance to sudden impact among other types of plastic pallets. A reversible plastic pallet makes it easy to flip over when one surface is dirty. When the appearance of the surface does not comply with your standard, another surface of a reversible plastic pallet gives a reliable impression of the plastic pallet. Therefore, the versatile reversible plastic pallet helps to use either side of the pallet and contributes to fast and easy material handling.

The reversible plastic pallets are cost-effective, and their life span is longer since both sides can be used as the pallet surface. Hence, it reduces pallet-related expenses and costs. From an environmental point of view, reversible plastic pallets are more environmentally friendly than other types of plastic pallets. Since using reversible plastic pallets minimizes the need for replacement with new plastic pallets on repeated trips.

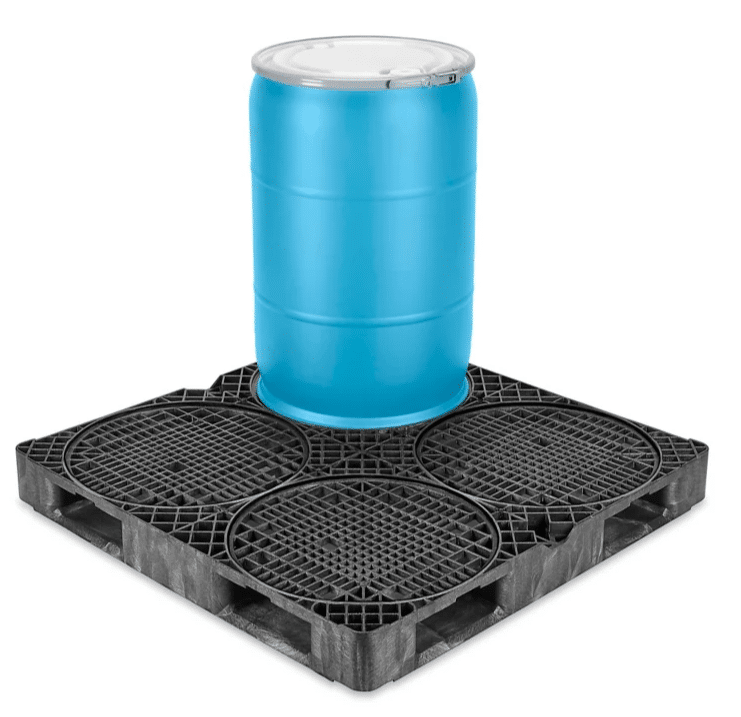

Drum Plastic Pallet

A drum plastic pallet is ideal for storing and transporting drums or barrels in any application and industry. The drum plastic pallet is uniquely designed with circle-raised edges to keep the drums safely on the pallet.

The drum plastic pallets are typically made from HDPE or PP plastic materials. These material guarantees impact and have hit resistance stability and provide excellent resistance to moisture, chemicals, and weather conditions. HDPE or PP plastic materials are tough and dense, making the drum plastic pallet durable during transportation. Hence, they can absorb sudden shock and retain strength. Normally, four drums can be put on a plastic drum pallet, but other sizes for drum plastic pallets are also available. Additionally, drum plastic pallets may have contaminant sump or basin. It helps to control any potential leaks, spills, or drips from the drum regardless of whether the liquid is hazardous or non-hazardous. Using drum plastic pallets ensures the safety of the place where the drums are in workplaces, warehouses, vehicles, etc. Furthermore, it reduces environmental risks and hazards by controlling unintentional leakage of the liquids and spreading.

Spill (Control) Plastic Pallet

The spill control plastic pallets are widely used in chemical processing, pharmaceuticals, agriculture, and industries involving liquids, chemicals, or hazardous substances where material leaks should be prevented from spreading. In other words, in any industry where the fluid can leak on the floor (production hall, warehouse, etc.) or in logistics applications and shipping containers or trucks, the spill control plastic pallet can answer the demands for controlling the spill and containment.

Spill control plastic pallets, like other types of plastic pallets, are usually made from durable plastic material, HDPE or PP material. They are are chemical resistant and make the pallets strong from rusting and corrosion, which contributes to the use of spill plastic pallets in many industries in contact with a wide range of material without risk of degrading.

The spill plastic pallets noticeably help the environmental concerns by preventing hazardous material from seeping into the ground or water supply. The design of spill control plastic pallets aims to manage any spillages during the production process, storage, and transporting. Typically, this plastic pallet has built-in sumps or basins/trays to collect the spilled material. Additionally, cleaning up the location is easy and fast in case a spill happens since the substances are contained in the basin/try, and consequently, the respective costs of cleaning decrease.

Spill plastic pallets hinder the possibilities associated with accidental spills and leaks and are the best alternative for industries with restricted environmental regulations and safety standards regarding spill contaminants.

Jumbo Bag Plastic Pallets

The plastic jumbo bag pallet is one of the special types of plastic pallets designed specifically for transporting and storing bulk materials. The bulk materials are usually kept in a jumbo bag known as a bulk bag or FIBC (Flexible Intermediate Bulk Container). The jumbo bag refers to a large, versatile, durable woven polypropylene fabric designed to be placed on a pallet for easier handling and transport.

As the full jumbo bag weight cannot be evenly distributed on top of the typical plastic pallet, it hinders the functionality of storage and transporting and causes pallet damage. However, the jumbo bag plastic pallet solves this issue. It has raised edges in a square shape or molded-in grooves to hold the jumbo bag in place securely, provide stability, and facilitate movement using forklifts or pallet jacks. Therefore, the pallets prevent the jumbo bag from sagging and sliding during handling and transportation. The stackable plastic jumbo bag pallets contribute to very low space consumption when the pallets are not under load.

The jumbo bag plastic pallets are typically made from HDPE or PP plastic materials, providing excellent resistance to moisture, chemicals, and weather conditions. The jumbo bag plastic pallets are usually used in industrial settings like agriculture, construction, and manufacturing to transport and store bulk goods like grains, chemicals, or minerals.

Heavy-duty Plastic Pallets

Heavy-duty plastic pallets are designed for storing, transporting, and stacking heavy cargo. They are constructed stronger and more durable, particularly at high load-bearing capacity, than the lightweight and medium-duty plastic pallets. The main purpose of producing heavy-duty plastic pallets is to bear significant loads in static, dynamic, and racking modes and other applications. The heavy-duty plastic pallets are ideal for storing and stacking heavy products or uneven products like jumbo bags in high racks. At the same time, the self-weight of plastic pallets is not too heavy to hinder operators’ jobs.

Heavy-duty plastic pallets open opportunities for greater operational efficiency and guarantee trouble-free operations compared to other types of plastic pallets. Because of the strength, high impact, and hit resistance, as well as the increased durability of heavy-duty plastic pallets, their lifespan is considerably longer, and there is no need to change them so frequently, which contributes to cost savings in your industrial circulation.

Furthermore, heavy-duty plastic pallets are tough, dense, and extremely robust during transportation and logistics applications. Hence, they can absorb sudden shock encountered in the industry and maintain structural integrity and strength. Consequently, the heavy-duty plastic pallet is the best alternative for everyday internal tough industrial operations. In short, heavy-duty plastic pallets are ideal for heavy-duty processing in warehouses, conveyors, pallet shuttle systems, racking systems, ASRS systems, mechanized handling of inventories, and forklift and pallet trucks. That is why many call heavy-duty plastic pallets warehouse plastic pallets since, in any internal circuits, we demand the strongest and the most durable plastic pallets.

Conclusion

As explained in previous articles, the need for plastic pallets is determined. Different types of Plastic pallets is a vital tool in any supply chain, assisting the logistics process, stacking, transporting, and storing the goods optimally. The need for plastic pallets is vivid; you only need to recognize and clarify your demands from a plastic pallet. Many plastic pallet manufacturers are available to answer your requirements. IranPlast Group is here to offer you different types of Plastic Pallets based on the injection molding method. We use Virgin HDPE and PP Copolymer injection grades to produce various plastic pallets. Based on your applications, we are doing our best to match the plastic pallets. For any more information and technical data, please feel free to contact us.

Frequently Asked Questions about plastic pallets types considering their applications:

What is a nestable plastic pallet?

The nestable plastic pallets can stack inside one another when not in use to save space and reduce transportation costs.

Where can we use nestable plastic pallets?

The nestable plastic pallets are commonly used for lightweight applications in food and beverage, pharmaceuticals, export, distribution, and retail industries.

What is a rackable plastic pallet?

The rackable plastic pallets can tolerate a defined cargo weight on the racking systems, pallet shuttle systems, forklifts, pallet trucks, hand-jacks, etc., without sagging or bending on racks. The rackable plastic pallets can tolerate loads by making a bridge between two supports in a racking system.

Why are rackable plastic pallets used?

The rackable plasticpallets are ideal for maximizing the storage space, safe storage, organization, accessibility, and optimization of storage efficiency. They enable companies to use the air space efficiently, clear up floor space when needed, and be cost-effective by taking advantage of air space.

Where can we use rackable plastic pallets?

The rackable plastic pallets are typically used in storage facilities, warehouses, processing and manufacturing environments, static storage, and stack loading and distribution centers equipped with racking and pallet shuttle systems.

What is an export plastic pallet?

Export plastic pallets are designed for transporting goods and products in short or long distances. The export plastic pallets are extremely light but stable, sturdy, and durable enough to endure rough handling during transportation and ensure the safety of the goods.

Where can we use the export plastic pallets?

Export plastic pallets are mainly used for one-trip applications as packaging tools that have to be made at a lower self-weight. They are commonly used in air freight sections, health and beauty products, pharmaceuticals, food and beverage, food processing, and dairy.

What is a one-way plastic pallet?

One-way plastic pallets are the same as export plastic pallets, which answer to the demands of sending palletized cargo when returning pallets to their origin is zero.

What is the difference between export and nestable plastic pallets?

Export plastic pallets can also be nestable; however, all nestable plastic pallets may not answer export plastic pallet characteristics, such as lightweight.

What is a display plastic pallet?

The display plastic pallets are designed for presentation purposes; hence, they are typically lightweight for easy movement by users and cost-effective. They must be compatible with forklifts and hand jacks for fast and easy handling.

Where can we use display plastic pallets?

Display plastic pallets are normally used in retail environments, groceries, supermarkets, malls, exhibitions, trade shows, e.g., in-aisle or end-of-aisle displays, or other settings where goods are showcased, visuality and accessibility are essential.

What is a hygienic plastic pallet?

A hygienic plastic pallet is made from materials that comply with food and are easy to clean and maintain in industries where contaminate-free structure, cleanliness, and sanitation are crucial. These hygienic plastic pallets are designed with perfected solid smooth surfaces without any crannies, seams, chinks, or hidden places, preventing the risk of contamination and the spread of pathogens, mold, and bacteria.

Where can we use hygienic plastic pallets?

Hygienic plastic pallets are widely used in industries where sanitation and cleanliness are essential, including food-related applications, pharmaceutical manufacturing, healthcare, laboratories, agricultural and horticultural, cosmetical sector, retail, and distribution settings.

What is a reversible plastic pallet?

A reversible plastic pallet can be used on either side facing up and bear significant loads in static, dynamic, and racking modes. Its versatility makes it easy to flip over when one surface is dirty. The strength, high hit resistance, and long lifespan make the reversible plastic pallet cost-effective and ideal for many industrial applications. Reversible plastic pallets are more environmentally friendly due to minimizing the need to replace new plastic pallets on repeated trips.

Where can we use reversible plastic pallets?

Reversible plastic pallets can be used in any industry. Particularly those that need heavy-duty plastic pallets, such as automotive, petrochemical, chemical, beverage wire & cable, or parts manufacturing.

What is a drum plastic pallet?

A drum plastic pallet is perfect for storing and transporting drums or barrels in any application and industry. Using drum plastic pallets ensures the place’s safety and reduces environmental risks aby controlling unintentional leakage of the liquids.

Where can we use drum plastic pallets?

Drum plastic pallets are mainly used in industries involving liquids, chemicals, or hazardous substances. Drum plastic pallets are uniquely designed for storing and transporting drums or barrels in any application and industry.

What is a spill control plastic pallet?

A spill control plastic pallet is designed to manage spilled liquids. It typically, has built-in sumps or basins/trays to collect the spilled material. These pallets should made from durable plastic material, HDPE or PP material, that resists corrosion. Storing and shipping barrels, and drums that may leak with spill control plastic pallets enable us to collect the spilled material before spreading it anywhere but in its basin.

Where can we use spill control plastic pallets?

Spill control plastic pallets are primarily used in industrial settings to container and manage liquids, in particular dangerous substances. The spill control plastic pallets help to prevent hazardous material from seeping into the ground or water supply. The design of spill control plastic pallets aims to manage any spillages during the production process, storage, and transporting.

What is a heavy-duty plastic pallet?

Heavy-duty plastic pallets aim to bear heavy load capacity and are tough, dense, and extremely robust during transportation and logistics applications. The heavy-duty plastic pallets are ideal for storing and stacking heavy products or uneven products like jumbo bags in high racks.

Where can we use heavy-duty plastic pallets?

Heavy-duty plastic pallets are the best alternative for everyday internal tough industrial operations.T hey are designed for heavy-duty processing in warehouses, conveyors, pallet shuttle systems, racking systems, ASRS systems, mechanized handling of inventories, and forklift and pallet trucks.

What is a jumbo bag plastic pallet?

A jumbo bag pallet with raised edges or molded-in gutter guarantees secured storage and transport of jumbo bags. The bulk material in the jumbo bag can be handled securely by holding the jumbo bag in place, and preventing sliding during movements.

Where can we use jumbo bag plastic pallets?

The jumbo bag plastic pallets are usually used in industrial settings like agriculture, construction, and manufacturing to transport and store bulk goods like grains, chemicals, or minerals.