What is a box pallet?

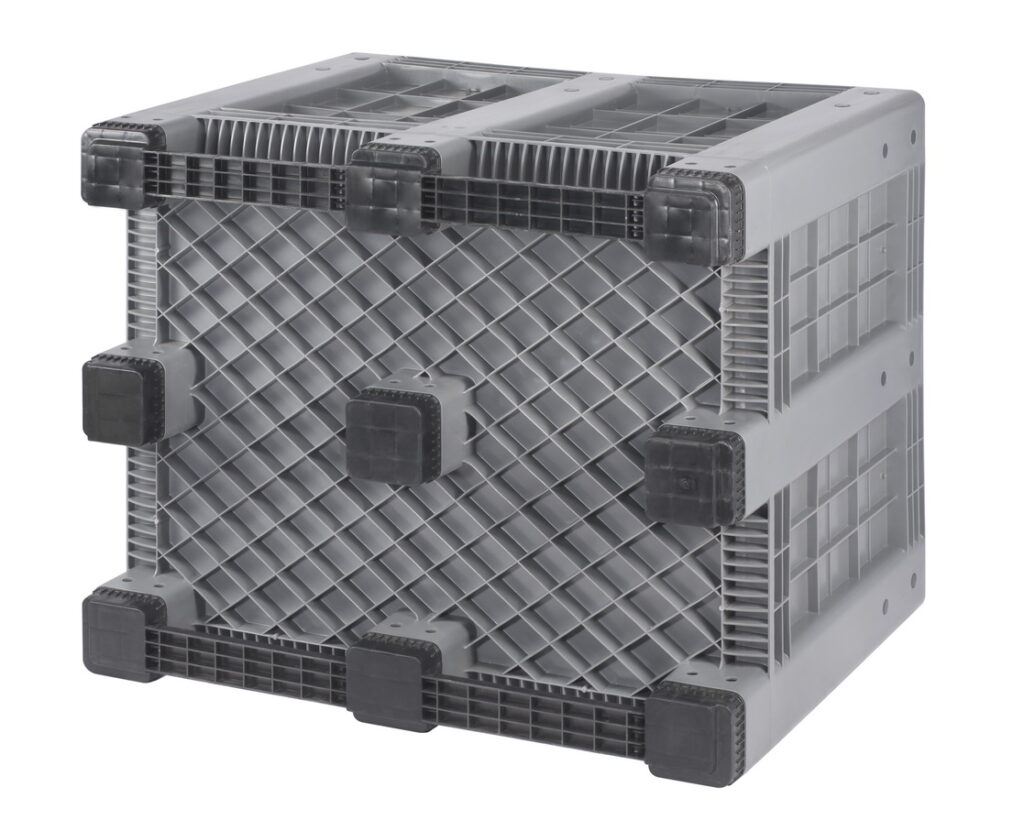

Before talking about the Plastic Box Pallet, let’s see what Box Pallet is. Pallet Box, Box Pallet, or bulk container, no matter what we call it, is a combination of pallets and bins means a pallet-sized box emphasizes keeping both advantages and applications of a pallet and a big container. A bulk pallet container has at least three vertical sides that can either be rigid, collapsible, or even entirely removable. Box Pallets are designed for mass storage, heavy shipping, and handling. Today’s industries are involved in the fast improvement of the entire supply chain, causing challenges and rapid demand changes. When it comes to bulk handling, logistics & transports, storage, and stacking a pallet box would be a reasonable solution.

What are box pallets made of?

Box pallets can be corrugated cardboard, fiberboard, plastic, metal, or wood. Here we are focusing on Plastic Box Pallets. Plastic bulk pallet containers are manufactured from virgin or recycled HDPE (High-Density Polyethylene). The material type depends on the application’s purposes. Virgin materials are recommended for hygienic use with high regulations and standards, such as in pharmaceutical or food industries or high performance. For many others, we can use recycled or mixed HDPE material. The finished product, i.e., plastic box pallet, still has enough strength to tolerate heavy load products and non-hygienic goods. Plastic material has privileges for easy cleaning and sanitizing in industrial washing machines. Due to their injection molding construction, plastic bulk containers are produced in one shot injection process, caused making a homogeneous, smooth, and gap-free structure.

What is a plastic box pallet used for?

The plastic box pallet answers various demands for almost any manufactured goods in any context of activities and industries; logistics, storage, distribution, FMCG, agricultural, metal, food processing/production/retailing, food ingredients, beverages, fishing, automotive and batteries, polymeric and plastic, pharmaceutical, textile, recycling, chemicals, waste management, industrial types of machinery equipment, mechanical and appliance components.

Plastic bulk containers are ideal for heavy-duty, voluminous, bulk, or tiny products. They facilitate and improve the flow of maneuvering complicated products systematically, shorten the time of moving the goods, and increase the volume of each run.

The plastic bulk pallet containers are stackable and easy to handle with forklifts and hand-jack. Hence, assist in stacking, transporting, and storing any products, especially those with heavy loads or the weight is not evenly distributed. Plastic pallet boxes decrease the cost of transportation and storage per trip and, consequently, the total cost of these factors per product.

In logistics:

As part of any supply chain, the logistics process demands accurate and timely storage and transportation. An essential factor is having strong and durable equipment for stock and maneuvering the goods in successful logistic management. Using plastic bins opens the opportunity to stack a noticeable number of goods simultaneously, saving space in a healthy and safe situation. Furthermore, plastic box pallets facilitate and accelerate the number of goods that need to be moved from point A to point B. Consequently, the labor costs will reduce significantly.

In the food industry:

The food and beverage industries must follow restricted standards and demand fast-changing requirements. The products, i.e., food and beverage, are sensitive goods with high regulation and necessitate safe and hygienic stacking, storing, and transporting at any step from production to the customer/consumer.

Plastic box pallets with rigid corrosion–resistance, waterproof, and contaminant–free structures optimize the loading and keeping of the goods in a safe, clean mode. Stackable plastic pallets and bins with rounded edges, protective frames, and robust walls protect the loaded products from a hit, tearing, contaminants, impact, foreign objects, and humidity. Plastic box pallets increase the safety and freshness of the goods during storing, stacking, and long distances trips. All residues are removable after production thanks to one-piece molding and the plastic nature. Therefore, the plastic box pallets are free of absorbing and hosting bacteria, mold, and fungi. Plastic pallet boxes for food and beverage purposes are produced using food-grade HDPE material comply standards in contact with food. In addition, plastic bulk containers have a smooth external and internal structure that contributes to easy cleaning, high sanitation, and hygienic properties.

In the agricultural industry:

On the one hand, the agriculture industry requires voluminous boxes with high resistance to long-term intensive use and a low breakage rate. On the other hand, the industry and respective distributors and wholesalers demand bulk containers with hygienic properties suitable for the field and agricultural products. The plastic box pallet for agricultural products may remain in the field for a long time; therefore, besides using food-contact material, the UV additive used in the production reinforces the plastic bins against color fading from sun exposure. In short, we can use plastic pallet boxes from the harvest field until distribution to FMCG. Besides using a plastic pallet container for collecting & picking, storing, and transporting horticulture products (fruits and vegetables), the plastic box pallet is a reasonable choice for fertilizer storage.

In manufacturing sites:

Manufacturers of material, semi-finished products, and finished products require temporary short-term storage in the production line. The compatibility of plastic box pallets with the automatic production and handling systems open a new door for producers to excessive use of plastic bulk containers for different purposes for various applications in factories, production lines, manufacturing, waste management, as well as short and long-term storage of upstream and downstream goods and material, transportation and distribution.

On the one hand, produced part/product should be collected in the production line before storing it in the warehouse. On the other hand, many manufacturing companies need raw materials or semi-finished products to accomplish their production. The stackable plastic box pallets with robust bases and anti-corrosion structures compatible with forklifts and hand-jacks optimize these handlings. Thanks to one-shot injection molding, the plastic bulk pallet containers are homogenized without holes, cracks, or penetration gaps and are ideal for keeping chemical liquids, hazardous substances, and tiny parts. The strong structure of the plastic bulk containers allows manufacturers to have safe and strong bulk handling, stacking, storage and transportation at any step of the supply chain.

Plastic box pallet types:

Generally, plastic pallet boxes are divided into two types in terms of the type of usage; solid walls and perforated walls. From a dimension perspective, the bulk pallet containers can be produced in any size. Based on the region and market generally, two sizes are more common, 1200X1000 mm and 1200X800 mm, between users and, consequently, manufacturers usually supply these two sizes.

Plastic box pallets with solid walls

The plastic box pallet with solid walls is recommended for heavy loads handling goods, bulky or complicated to maneuver. The solid frame causes a protective and strong structure which contributes to dynamic and static loads. If the goods are not heavy weight, still this type of plastic bulk container can be a reasonable alternative for small parts such as nuts and screws, powders and granules such as any plastic material or washing machine power, or liquids such as detergent. In addition, solid plastic bin boxes are ideal for handling some sectors of the food industry, for example, the bakery process and the seafood sector. The solid base, without gaps and holes, protects the goods well in producing, storing, stacking, transporting, etc.

Plastic box pallets with perforated walls

In terms of producing a perforated model, the plastic box pallet is divided into two types; ventilated sides & closed bottom or ventilated walls & bottom. The perforated plastic box pallet is designed to store, stack, and transport products that need natural ventilation, air circulation, and freshness while keeping and traveling while enjoying the robustness of the box. Ventilated plastic box pallets are ideal for maintaining the goods without the wordiness of moisture that causes the growth of bacteria, fungi, and molds. Ventilated box pallet is mostly used in the agricultural industry, from fruit picking steps in the field to distributing them to the store. The perforated plastic bulk bins increase the health of the loaded goods in food-related applications, for example, perishable goods during transportation and storage in cool warehouses

Accessories and customization

Plastic box pallets can be configured with legs, skid runners, castors, RFID tags/ label holders, drain valves, foldable wall(s), and plastic lids to adjust for the special applications that users require. Any accessories upgrade the operation and handling of a plastic bulk pallet container efficiently in different contexts like facilitating storage, racking, and maneuvering.

Legs or skid runners

As mentioned in the definition of Pallet Boxes, the bottom of boxes plays the role of pallets. Therefore, forklifts manage the maneuvering of empty or full box pallets regardless of what accessories are attached and applied. Leading to the type of application, a bulk pallet container may need to have feet or may need to have skid runners. For example, container pallets with legs cannot be used for racking, so skid runners help to store the plastic bulk container on the racking systems.

Plastic lid

Some loaded goods in a plastic box pallet must be covered and protected during stacking, storing, and transportation. The plastic lid on each plastic bin closes the entrance 360 degrees, keeping the inside safe and secured far from entering outside threats. The cover on a box pallet noticeably reduces unexpected damages and the vulnerability of the products. The plastic lid of the plastic pallet container is stackable, and consequently, boxes can be stacked easily. The plastic pallet box with the lid can be strapped, sealed, or locked, and therefore, we can store or transport the goods sealed. The lids are stackable, strong, and durable, like plastic box pallets. Each plastic bin perfectly fits on top of the below plastic bins with lids.

Wheels & castors

Mounting wheels or castors (with or without brakes) beneath the box pallets incredibly facilitates the short-distance movement and handling of the boxes. For example, users in a production line can move the bulk pallet container from one place to another, especially in narrow areas. The wheels help the worker drive and handle the plastic pallet boxes more easily in manual sanitizing and washing.

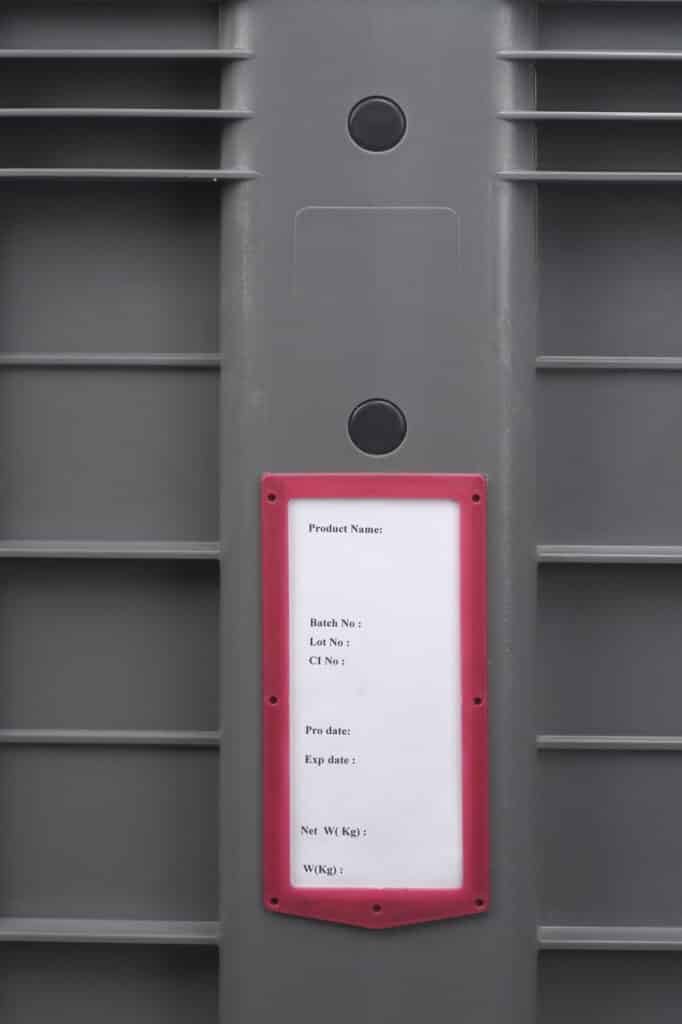

RFID tags/ label holders

In smart inventory management, box pallet trips are registered automatically. An RFID tag attached to each plastic box pallet assures warehouse managers to trace the component and a plastic bin accurately. Fast upgrading in the supply chain, especially in logistics, requires accurate data and reliable integration of the entire chain. Box pallets with RFID tags help to have an integrated overview of the product’s journey, such as FMCG and wholesalers. Label Holders attached to each plastic pallet box help to recognize which type of products are stored in each plastic bulk container. Based on the user’s demand, any information can be cited on the label. The labels can be changed or removed quickly when the application changes.

Foldable wall(s)

The plastic box pallet can be configured to have one or more foldable sides, also known as a collapsible or drop-door plastic pallet box. Plastic collapsible bins provide a highly versatile storage option. Hinged walls allow the user to have better access to the bottom of the plastic bulk pallet box. So, the manual emptying of the plastic bulk container is easier.

Color

Thanks to the injection molding process of HDPE, a plastic pallet box can be produced in any color shade, providing the possibility to use personalized colors for your applications.

Drain valves

Drying after washing or emptying the unwanted liquid accumulated in the plastic box pallets are essential in some context. Drainage holes, drain valves, and outlet faucets for liquid draining provide this purpose.

Environmental impact concern:

The plastic pallet box is manufactured from plastic raw material and, therefore, can be considered as a negative impact on the environment. Many say plastic pallet boxes cannot be an absolute solution for Green Supply Chain Management. However, Plastic is privileged to use rather than wooden, corrugated cardboard, fiberboard, etc. due to its reusability and long lifespan. In addition, plastic bulk containers can be recycled many times and returned to circulation. The scraped material can be reused as completely new plastic products.

IranPlast Group is one of the leading manufacturers of Plastic Pallet Boxes in the Middle East. All the above information and explanations are our know-how and ready to share more details upon request. Please feel free to contact us if you are interested in any type of Plastic Pallet Boxes. We provide you with any customizations you need on the requested plastic bulk pallet containers.

Frequently Asked Questions about Plastic Box pallets:

- What is a plastic pallet box?

A plastic pallet box is a combination of a large bulk container and a pallet; the plastic bulk pallet container keeps both the plastic pallet and plastic container’s advantages and applications.

- What are box pallets made of?

Box pallets can be corrugated cardboard, fiberboard, plastic (HDPE or PP), metal, or wood.

- What is a plastic box pallet used for?

In many industries, plastic pallet boxes are used. For example in logistics, storage, distribution, FMCG, agricultural, metal, food processing/production/retailing, food ingredients, beverages, fishing, automotive and batteries, polymeric and plastic, pharmaceutical, textile, recycling, chemicals, waste management, industrial types of machinery equipment, mechanical and appliance components.

- Are plastic box pallets recyclable?

Plastic box pallets nearing the end of their lifespan can be recycled and reused the material for new plastic products.

- Can plastic pallet boxes stack?

The plastic bulk pallet containers are stackable 5 to 6 boxes and easy to handle with forklifts and hand-jack.

- Can we add accessories to plastic box pallets?

Different accessories can be added to a plastic pallet box based on an application. We can apply feet, skid runners, castors, RFID tags/ label holders, drain valves, foldable wall(s), and plastic lids.

- What types of pallet boxes do we have?

Application-wise, plastic pallet boxes have two types; solid walls and perforated walls. From a dimension perspective, the plastic box pallet is mostly produced at 1200X1000 mm and 1200X800 mm.

- Are plastic pallet boxes suitable for liquid storage?

Plastic box pallets are homogenized without holes, cracks, or penetration gaps due to one-shot injection molding. Hence, plastic bulk pallet containers are ideal for keeping chemical liquids and hazardous substances.

- Are plastic box pallets cleanable?

Plastic pallet boxes have a smooth external and internal structure that contributes to easy cleaning, high sanitation, and hygienic properties.