Never underestimate domestic waste since waste can become valuable material again! The most important issue is to follow the waste management system implemented by the government and municipalities of your city. On the one hand, the opportunity to organize and collect the waste opened a way to systematically keep the trash out of the site more securely and healthily. On the other hand, it helps the environment by collecting disposal for recycling, composting, or incineration burying purposes. The wheelie bins or wheeled waste bins usually refer to large containers with castors or wheels and axel facilitate keeping and moving domestic trash destined for disposal. Apartment complexes or residential areas, schools, hotels, and business offices create household waste daily. Mobile garbage bins with lids secure and simplify storing waste until collection day. Waste bins are made in different sizes to cater to any household size users and waste volume or fitting in the spaces allocated for waste bins.

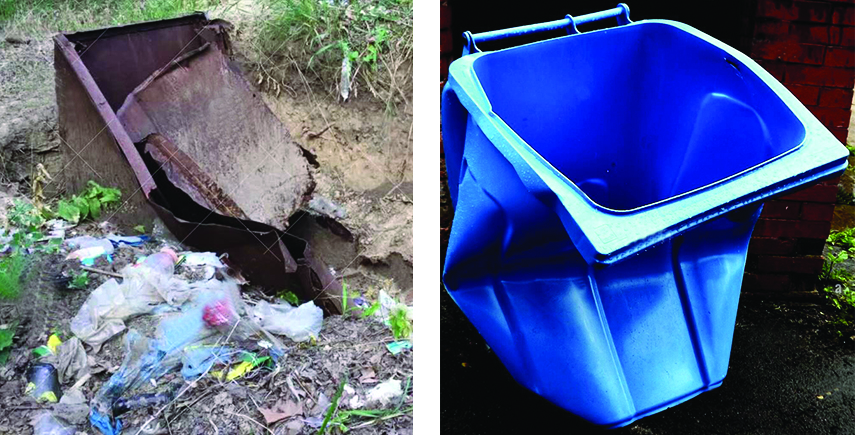

Plastic vs. Metal Waste Bins

Usually, mobile garbage bins are made of two materials: Plastic Waste Containers and Metal Waste Containers. Plastic Waste bins are made of High-Density Polyethylene (HDPE), a durable material for plastic products. Metal Waste Bins are made of galvanized or non-galvanized stainless steel with different thicknesses. Stainless steel is an alloy of Iron with a minimum of 10.5% Chromium. Regardless of the size of mobile garbage bins, here, we are studying the similarities and differences of the wheelie waste bins in terms of material, Plastic Waste Containers vs. Metal Waste Containers, enabling us to have a better outlook on which material type suits our region.

Waste Bins Criteria

Ease of handling

Usually, plastic waste bins are lighter than metal waste bins. Therefore, manual transporting of a plastic waste bin full of trash is easier than a metal waste bin moving around or into a lifting vehicle.

Hygienic concerns

Due to the nature of HDPE material and body deep color, plastic waste containers can be cleaned easier. The germs and dirt can be removed from a plastic surface easier than from a metal surface. Using detergents and cleaning liquids do not harm the color or texture of the plastic. The rust concerns about using water or hot steam on the plastic waste bins are zero compared with metal and steel wheelie bins.

Weather resistance

Extreme weather conditions, humid and rainy climates, and hot and sunny weather play a vital role in outdoor mobile garbage bins’ durability. Metal wheelie bins rust and corrodes more than plastic; hence, the frequency of repairs and replacements over the life cycle is significantly higher than Plastic. In other words, plastic-wheeled waste bins stand up in coastal areas, for example, longer than steel. However, exposure to the harsh sun may cause the plastic’s color to fade, while such issues are rarely seen in metal waste bins. Modern material engineering and special additives such as UV stabilizers solved this problem.

Safety concerns

Despite metal waste containers, plastic garbage bins have smooth surfaces without welding, preventing users’ injuries if some parts of a waste bin are broken and apart. However, plastic nature is more flammable than metal or still. Generally, a plastic product can ignite significantly sooner and quicker than metal. However, by adding an anti-flaming additive, we can increase higher ignition point if necessary, and therefore, the burning and firing can be controlled completely. Furthermore, even if the plastic waste bins get on fire, for example, by putting flammable waste into it, the plastic parts start to be welded instead of firing like wood.

Waterproof

Plastic mobile garbage bins are made in one shot injection molding process. Therefore, the body is homogenized without holes, cracks, or penetration gaps. This helps plastic waste bins to withstand water waste and any liquid inside the containers. However, metal waste bins may be partially sealed since welding different metal parts make them. They are vulnerable to cracks and holes that allow the waste liquid to penetrate outside.

Standards and regulations

The EN840 standard is the European standard setting out the basic standard for 2- and 4-wheeled waste containers focusing on comb lifting devices, dimensions, design, lid, casters/wheels type, and positioning and trunnions shape and positioning, performance requirements, Safety and health requirements, etc. Many waste management organizations emphasize not collecting wheelie bins that don’t meet this standard. Hence, plastic mobile garbage bins are the proper answer to meet these demands rather than metal waste bins.

Strength

Plastic mobile garbage bins are made of HDPE, which can withstand harsh materials like acids, alkalis, fungi & bacteria. HDPE waste bins are highly resistant to cracks, dents, and bending, especially in humid and windy weather. The plastic mobile garbage bins are durable and stronger against scratch and shock. It is also a good choice as a temporary tank for liquids and wet waste. Metal waste bins are stronger to tough uses and extreme heat and flame. Still, they can be deformed easier by receiving hits and are susceptible to rusting and corrosion during rainy days or wastewater.

Sanitizing and cleaning

We can easily and quickly clean plastic waste bins. They can be hot-washed, steam-cleaned, or chemically sterilized. Therefore, we can enjoy cleaner waste bins and reduce the risk of unpleasant odors remaining after the cleaning procedure. Furthermore, Printing or graffiti can be easily removed with non-toxic cleaners. There is a possibility to eliminate the faded prints and logos to provide a smooth surface for re-printing. However, metal garbage bins require a long and detailed procedure to remove such marks from the surface, considering the possible harm on the galvanized surface. Being cleanable is one of the most important factors in the waste bins and interface. Plastic is cleanable, one of the best properties of plastics, especially when it comes to waste containment, such as medical waste that needs special cleaning after emptying the bins. Having such results in metal waste bins is gained by using medical-grade stainless steel, which is costly.

Corrosion & dusting

Metal waste bins are vulnerable to rust or corrosion against wet conditions. Humid or rainy weather or wet waste can create such a condition. Exposure to extreme humidity for a long time causes major problems with metal waste bins. There is an increasing desire for organics collections, which needs an appropriate container to keep wet refuse enough for emptying and transporting purposes. Plastic mobile garbage bins, thanks to the nature of the anti-rusting of plastic, this type of wheelie waste bins can easily be the best choice for such purposes.

Noise prolusion

Opening and closing the waste bins and lifting and emptying them make noises that could be disturbing in residential complexes and hospitals. Although both types of mobile garbage bins, metal, and plastic, make noises, plastic waste bins make less noise prolusion, such as slamming and banging, compared with metal types.

Repairing

As explained above, mobile garbage bins are not vulnerable to rust or corrosion, but the material is susceptible to hot, fire, and severe hits. When the plastic starts to melt caused by fire or cracking and breaking by hard strikes, there is no way to repair the broken part of the bin; therefore, the plastic waste bin is destined for replacement. At the same time, metal waste bins are highly resistant to fire. The broken and damaged parts of metal waste bins can be repaired, although it needs time, equipment, and a reasonable budget to supply equipment and experts for such repairs.

Cost

Providing appropriate metal waste bins, i.e., made of stainless steel and galvanized metal waste bins, required quality steel sheets. The thicker the steel sheet, the stronger the metal waste bins. The pureness of steel also matters, e.g., 18/8 or 18/10 steel sheet. However, using thinker or quality steel, hot dip galvanization and welding, and integrating all parts are costly, around 1.5 to 2 times more than plastic mobile garbage bins.

Waste sorting

Nowadays, the awareness of sorting waste from its origin is rapidly increasing; therefore, the color of waste bins matters. Each color of the waste bin indicates which types of waste you can put in. By adding color additives, i.e., color master-batch, we can produce any color shade of the plastic waste bin. It is almost impossible to have different color shades of metal waste bins. Because coloring the surface of metal waste bins is removable by frequent use and weather conditions. Plastics will take it from here.

Customization

We can apply customization on the lid or body of plastic and metal mobile garbage bins, such as numerations, traffic labels, or printing the customers’ logos. However, plastic waste bins provide vaster ranges of customization, such as various colors of containers, different color shades of body and lid colored printing, and silk screens without worries of fading. In other words, plastic mobile garbage bins can be more stylish.

Durability

Plastic and Metal waste bins are durable if they are treated correctly. However, weather conditions, users, lifting equipment, and vehicles are the main factors hindering both models’ life spans. Usually, plastic-wheeled waste bins get less damage since the plastic body and lids are produced through one-shot injection to resist bending and deformation, while metal parts are welded to make the whole bin. The welding can be apart during emptying or harsh hits to the metal body.

Conclusion

To sum it up, the table summarizes the above explanations; Plastic Waste Containers vs. Metal Waste Containers. Each type has its advantages to select depending on where and under what condition you want to use the mobile garbage bin. If you are looking for quality Plastic Mobile Garbage bins in different sizes and colors, IranPlast Group can provide you with various types of plastic waste bins. For any more information please get in touch with us through https://iranplast.com/contacts/ and we will answer your demands immediately.

| Criterion | Plastic MGB | Metal MGB |

| Handling | High | Low |

| Hygiene | High | Low |

| Weather resistance | High | Low |

| Safety | High | Low |

| Waterproof | High | Low |

| Standards | High | Medium |

| Strength | Medium | Medium |

| Sanitizing | High | Medium |

| Corrosion & dusting | Low | High |

| Noise pollution | Medium | High |

| Repairing rate | Low | High |

| Cost | Low | High |

| Waste sorting | High | Low |

| Customization | High | Low |

| Durability | High | Medium |